Tokyo (December 16, 2024) – Konica Minolta, Inc. (Konica Minolta) today announced that the Company has launched the KM800H-MR, which supports various inks with an internal heater, as a new product of the industrial inkjet printhead KM800 series, which features a long throw distance.

Inkjet Technology Contributing to Higher Efficiency in the Logistics Industry

In the logistics industry, there is growing need for higher productivity due to an increase in cargo volumes. Compared to the method of attaching printed labels, direct printing using inkjet technology on industrial products, such as metals and wood, and other target objects, such as pharmaceuticals, food packaging, and corrugated cardboard, can increase the efficiency by reducing the downtime due to replacement of label rolls, and contributes to a lower environmental impact by reducing waste. Inkjet printing is also characterized by ease of design changes and production adjustments because the information to be printed can be changed flexibly. It is also applicable to small lots, helping reduce inventory losses. Notably, piezo inkjet is suitable for high-resolution printing in small areas and printing of complex designs, such as 2D barcodes, because of its printing capabilities and high image quality.

Konica Minolta has been working on “Improving fulfillment in work and corporate dynamism,” “Addressing climate change,” and “Using limited resources effectively” as its material issues through expansion of the inkjet printhead business, which contributes to higher efficiency of work processes and a lower environmental impact. Because this business can help reduce processes and handle small lots through direct printing on target objects in the logistics industry, Konica Minolta will further strengthen its capabilities to make proposals that contribute to higher productivity.

Values Provided by the KM800H-MR

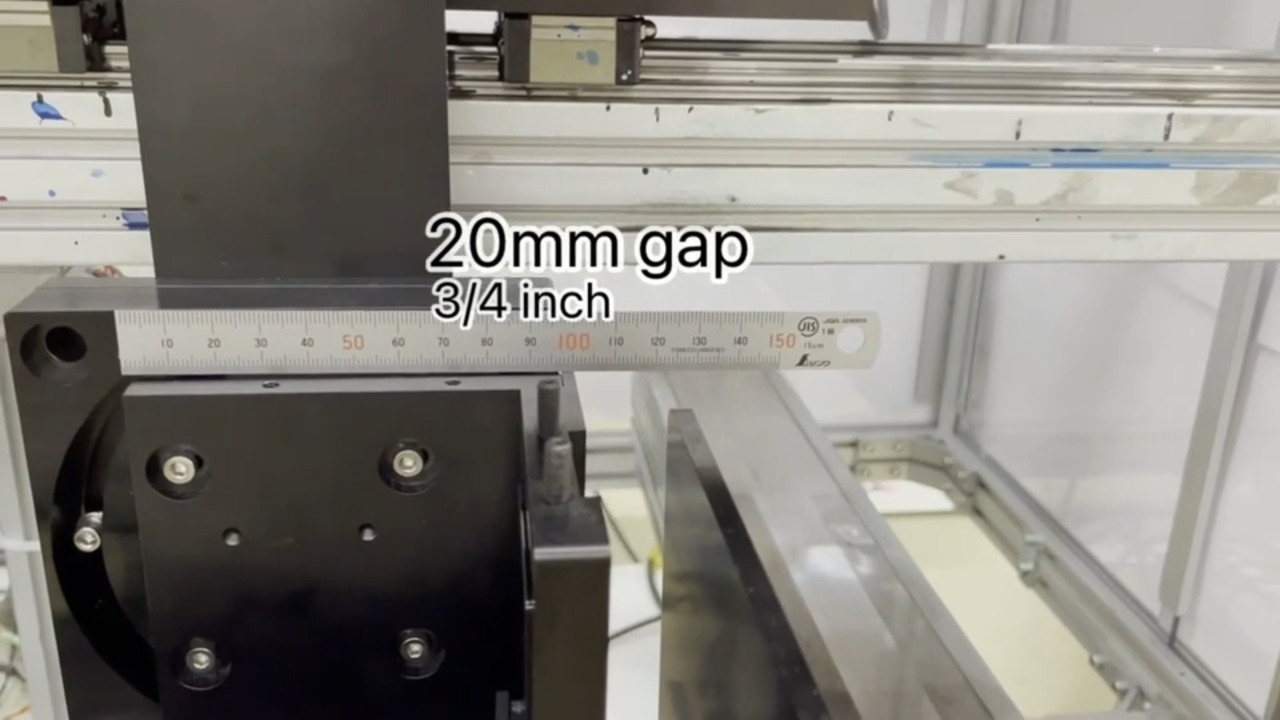

The KM800 series is characterized by superb long throw distance performance, which enables printing with high image quality on target objects 20 mm*1 away from the printhead, and the ink jetting stability. The long throw distance enables printing even on base materials where the distance from the nozzles to the printing surface varies, such as curved and rough surfaces. The distance between printhead and material should be enough to reduce the chance of head strike or material collision with the printhead.

Equipped with an internal heater, the KM800H-MR achieves a long throw distance even for UV inks, which are more viscous than water-based inks at normal temperature. The ability to support UV inks enables printing on non-absorbing base materials, such as plastics, films, and paper containers, expanding the coding and marking applications to bottles, packages, pharmaceutical packaging, and medical supplies.

Inkjet Jetting Technology of the KM800 Series

1. High-resolution printing on curved and rough surfaces realized by superb long throw distance performance

In general, the throw distance is about 1 mm to 3 mm. The greater the distance, the lower the likelihood of inks being placed accurately on positions, resulting in low image quality. Konica Minolta’s long throw distance technology realizes excellent high-resolution printing of 2D barcodes and other designs even when the nozzles and target object are 20 mm apart.*1 It is also suitable for textile printing because the distance between the printhead and the printing surface can be maintained to avoid interference by fuzz. It is also expected to be applied to DTS*2 for direct printing on three-dimensional objects because the narrow width between nozzle rows enhances the printing performance on curved and rough surfaces.

2. Usability in various usage environments by vertical placement and color printing

In general, an inkjet printhead is placed horizontally to print in the direction perpendicular to the target object. When printing on the side of a target object in the transfer process, it is desirable to place an inkjet printhead vertically in some cases. However, vertical placement causes the jetting characteristics to vary between nozzles in the upper positions and those in the lower positions, resulting in lower image quality. The KM800 series can perform printing while maintaining the image quality through stable ink jetting even in the vertical placement by applying Konica Minolta’s nano-fabrication and driving technologies. The inkjet printhead also supports color printing and can be used for various applications, including embellishment. The series also features a compact product design to facilitate installation in printing equipment.

Main Specifications of the KM800H-MR

| Product name | KM800H-MR |

|---|---|

| Number of nozzles | 800 |

| Print width | 56.4 mm |

| Resolution | 360 npi |

| Dimensions | W:99.0 mm × D:18.8 mm × H:119.0 mm |

| Jetting frequency | 18 kHz / 10 kHz |

| Drop volume | 5~22 pl / 30 pl |

| Ink Viscosity | 5~12 mPa・s |

| Heater | Yes |

| Inks | UV, oil, and solvent |

| Weight | 150 g |

| Grayscale level | 4 |

Customer Contact

Inquiry form of the IJ Component Business Unit, Sales Division, Konica Minolta, Inc.

*1 In the case of printing on corrugated cardboard. This is a verification example under Konica Minolta’s own driving conditions, and is not a guaranteed value.

*2 DTS: Abbreviation for Direct-to-Shape. It refers to direct printing on three-dimensional objects.