5 Reasons Why Copier Reps Need to Sell Contex Wide Format Scanners

The era of digital transformation is here, and nowhere is this more evident than in the growing demand for converting paper-based legacy wide-format documents into digital formats. State and local governments, along with many industries, are leading this charge to scan and archive their vast collections of blueprints, sepias, and engineering drawings. For copier sales representatives, this trend represents a golden opportunity to diversify their offerings and drive new revenue streams by selling Contex wide-format scanners.

Here are five compelling reasons why copier reps should add Contex scanners to their portfolio:

1. Meet the Needs of Digital Transformation Initiatives

Legacy Documents Need to Be Digital: Many organizations, especially in the public sector, are under mandates to digitize their archives. Compliance with initiatives like NARA (National Archives and Records Administration) and FADGI (Federal Agencies Digital Guidelines Initiative) standards requires high-quality digital copies of legacy documents.

Wide-Format MFPs Aren’t Enough: While wide-format multifunction printers (MFPs) can scan, their quality, speed, and features often fall short of the standards required for archival purposes. Contex scanners, designed specifically for wide-format legacy documents, deliver the precision needed for such critical tasks.

Position Yourself as a Digital Transformation Partner: By offering Contex scanners, copier reps can position themselves as key enablers of digital transformation, helping clients modernize their operations and preserve their historical records.

2. Capitalize on Superior Scanning Technology

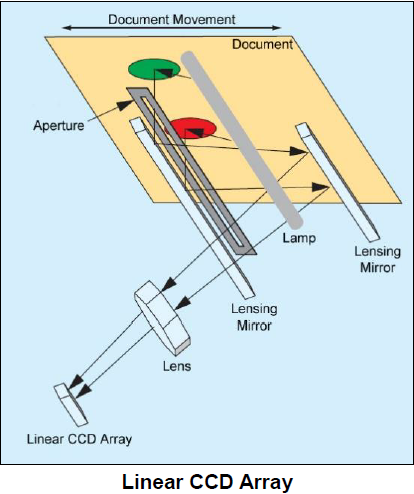

Contex scanners use CCD (Charge-Coupled Device) technology, which is far superior to the CIS (Contact Image Sensor) technology found in most MFPs. Here’s why CCD matters:

Unmatched Image Quality and Color Accuracy: CCD scanners use a high-resolution lens system and mirrors to capture a broader dynamic range, ensuring accurate color reproduction and capturing subtle details in blueprints and sepias. This makes them ideal for preserving intricate legacy documents.

Better Handling of Difficult Media: CCD scanners excel at scanning curled, wrinkled, or thick documents. Their greater depth of field ensures that even imperfectly flat originals are captured with clarity.

Ideal for Complex Originals: Many legacy documents feature fine lines and high-contrast details that CIS technology can’t handle effectively. CCD scanners excel in capturing these nuances, ensuring no detail is lost.

By emphasizing these technical advantages, copier reps can highlight the value of Contex scanners to clients seeking the best tools for their digitization projects.

3. Open the Door to IDP Solutions

Selling a wide-format scanner can be the first step in a larger conversation about Intelligent Document Processing (IDP) solutions.

Seamless Workflow Integration: Contex scanners can serve as the entry point to comprehensive document management systems. Once documents are digitized, clients often need software solutions to index, store, and retrieve them efficiently.

Upsell Opportunities: After selling a scanner, copier reps can introduce clients to IDP platforms that enable advanced features like optical character recognition (OCR), automated indexing, and integration with enterprise resource planning (ERP) systems.

Solve Real Business Challenges: By tying Contex scanners to broader IDP solutions, copier reps can address pressing client needs, such as reducing physical storage costs, improving compliance, and enhancing operational efficiency.

4. Differentiate Your Offerings in a Competitive Market

The copier and printer market is saturated, and competition is fierce. Offering Contex wide-format scanners can help copier reps stand out by addressing a niche yet growing need.

Specialized Expertise: Selling Contex scanners positions you as a specialist in wide-format scanning and archiving. You are the unique differentiator that sets you apart from competitors focused solely on copiers and MFPs.

Cross-Selling Opportunities: Wide-format scanning often complements existing copier and printer solutions. Clients who need a wide-format scanner are often the same ones purchasing wide-format MFPs, creating natural cross-selling opportunities.

Be the Go-To Vendor: By addressing the full spectrum of a client’s document management needs, from scanning to printing to archiving, you'll become an indispensable partner rather than just a product vendor.

5. Tap into a Growing Market Demand

The push for digitization is not a passing trend—it’s a long-term shift that’s only gaining momentum. Here’s why this matters:

Government and Industry Mandates: Many organizations face regulatory pressures to digitize their records, especially in sectors like construction, engineering, and government. These mandates often specify high-quality scanning requirements that Contex scanners are uniquely equipped to meet.

Preserve Historical Records: Digitization isn’t just about compliance; it’s also about preservation. Clients with aging blueprints and sepias understand the urgency of creating digital backups before these fragile documents degrade further.

Expand Your Addressable Market: By targeting sectors like architecture, engineering, and public works, copier reps can reach new clients with significant digitization needs, driving growth in untapped markets.

My Two Cents

For copier sales reps looking to stay ahead in a rapidly evolving market, adding Contex wide-format scanners to your lineup is a no brainer. These scanners not only meet the high standards required for digitizing legacy documents but also open the door to larger opportunities in digital transformation and document management.

By understanding the unique advantages of CCD technology, positioning yourself as a digital transformation partner, and addressing the growing demand for digitization, you’ll be better equipped to serve your clients and differentiate yourself from competitors.

The time to act is now and clients are looking for solutions that bridge the gap between their paper-based past and their digital future. With Contex scanners in your portfolio, you’ll be ready to meet that demand head-on and drive meaningful business results.

-=Good Selling=-