see attached file

Label Press

Lead for color wide format in Missouri

click image

Lead for Managed Network Services in New Jersey

Better Call Art with David Clearman "Recent Wins with Print Shops for Color Label Presses"

David Clearman and I chat about recent Print Shops placements along with reasons why print shops are moving forward with color label presses. Please subscribe to our YouTube channel to get instant notications when a new "Better Call Art" drops!

What's Hot With Color Labels!

I'm a huge fan of color label presses and that's because it's about putting ink on paper and it's so simple. Heck we've been putting ink (toner) on paper for the last forty years. Yes, there are some nuances with different substrates and laminates but it still comes down to putting ink on paper.

If you can sell digital color presses you can sell digital color label presses with a heck of a lot more GP for each device. The market potential is enormous especially since many states are now legalizing the use of weed.

Consider This Your Invite

David Clearman (Director of Marketing and PLS Sales at Muratec America) and I will be hosting and informal ZOOM chat on May 3rd at 4PM Est. Our talk track will be "What's Hot With Color Labels". Our chat should be about 30 minutes and we'll open up the mic for the last 15 minutes for everyone.

In addition David will raffle off a bottle of his famous bourbon for one lucky attendee. If you've been curious about digital color labels presses or you may think color labels presses offer a viable way to capture more dough and vast amounts of clicks then by all means tune in for our chat!

We're asking that everyone hit the RSVP button here (that's how we're keeping track of attendees). In addition once you hit the link you will see the ZOOM meeting link.

-=Good Selling-=

Color Label Press University "Glossary of Terms" Part Seventeen, Course One

What is your Post COVID19 recovery plan?

How will you make up the expected loss of clicks? Some are reporting that the click lost could be as much as 12% here in the US. Do you have the time or the financing to move forward with Managed IT Services?

For those that would like to stay with Imaging there are options. One of your options to is ride the wave of growth and migration of print.

Label Press University

At the top of each blog you'll see ![]() . Clicking that link which is at the top of each blog will then bring you the collection of blogs for Color Label Press University. It's pretty neat, you'll see all of the blogs that we've posted for an easier read and simple way to toggle from blog to blog.

. Clicking that link which is at the top of each blog will then bring you the collection of blogs for Color Label Press University. It's pretty neat, you'll see all of the blogs that we've posted for an easier read and simple way to toggle from blog to blog.

Color Label Presses can be used as seeding devices in larger Print4Pay opportunities, or help that dealer or rep get a conversation going with an account where they have never had any traction with MFP's or IT services. In addition, the competition is ripe for takeover. Let us not forget about the GP!

The market for full color digital labels in huge and the potential to make some serious commissions is enormous. BTW, isn't that why we're in this crazy business?

Color Label Press University "Glossary for Pressure Sensitive Labels" Course One (Sponsored by Muratec a Konica Minolta Company)

Piping

Also known as tunneling, a condition occurring in an incompletely bonded laminate characterized by release of longitudinal portions of the substrate and delamination of these portions to form these pipelike structures. The material fails to adhere to release paper or film tightly enough and a line of air forms between them. Usually starts at one edge and works across web.

Pitch Diameter The measure of a gear or cylinder, determined by diving the circumference by Pi (3.1416).

Plasticizer A substance added to materials to impart softness, flexibility, workability, elongation and dispensability.

Plasticizer Migration The migration of liquid plasticizers from some plastics into an adhesive and/or face material. Often causes excessive softening or degradation of adhesives.

Plasticizer Resistance Plasticizers can migrate into adhesives and/or inks and cause a breakdown, resulting in loss of adhesion to the substrate. If

the adhesive or ink is formulated to resist the plasticizer, the breakdown may not occur.

Plate The image carrier in letterpress and flexographic printing.

Plate Cylinder There are two types of plate cylinders; the integral, with the shaft a permanent part of the body and the de-mountable, in which the shaft is removable to receive a multiplicity of bodies of varying diameters, and in some cases face widths. These plate rolls are undercut in their diameter so as to accommodate various thicknesses of mounting tape and plate materials.

Platen Press Printing press in which a flat surface bearing the paper is pressed against a flat surface bearing the inked type. PLIABILITY

See flexibility.

Ply Each layer in a multi-layered structure.

Point Printer's unit of measurement to designate type size. There are 12 points to a pica; approximately 72 points to an inch. Also, a term used for an expression of thickness of a sheet of material in one-thousands of an inch increments, I.e. 7 point = .007" thick.

Poise The unit of viscosity, expressed as one dyne per second per square centimeter.

Polar Solvent Solvents with oxygen in their molecule, I.e. alcohols, water, esters, etc.

Polarity Refers to the relative surface charge of the material, resulting from the molecular structure of the adherent surface.

Polycarbonate A high clarity film having the versatality of acetate with the durability of polyester.

Polyester A strong film having good resistance to moisture, solvents, oils, etc., usually transparent, although available with opaque

and metalized finish. A clear complex ester formed by polymerization or condensation. Excellent strength, clarity and dimensionally stable.

Polyester Liner A polyester film that is silicone release coated. It provides an excellent die-cutting surface and is also used on overlaminating films to provide a smooth, glass-like surface of adhesive.

Polyester Metalized Film A clear polyester film, vacuum metalized on one side to provide a metallic look.

Polyester Overlam A clear, glossy polyester film coated with clear acrylic adhesive. Can also be supplied with a matte surface.

Polyethylene A tough, stretchy plastic film having very good low temperature characteristics. Also used a great deal for producing semirigid

recyclable bottles.

Polymer A compound formed by the reaction of simple molecules called monomers, having functional groups that permit their

combination to proceed to high molecular weights under suitable conditions. A long-chain molecular structure.

Polymerization A chemical reaction initiated by a catalyst, haet or light, in which monomers and/or oligomers combine to form a polymer.

Polypropylene Similar to polyethylene but stronger and having a higher temperature resistance. Various thermoplastic plastics are

polymers of propylene; excellent clarity. Also used in various thicknesses in the printing of labels as well as backing or liner materials.

Polystyrene A thermoplastic produced by the polymerization of styrene. The electrical insulating properties are outstandingly good and

the material is relatively unaffected by moisture.

Polyvinyl Refers to a group of resins formed by polymerizing various vinyl monomers.

Polyvinylidene Chloride A usually very thin transparent film with excellent resistance to acids, water and organic solvents. Saran.

Poor Trapping Condition in wet printing that results when less ink transfers to previously printed ink than to unprinted paper. Also called under-trapping.

POP Point of Purchase. The location at which a product is sold, the store or retail counter.

POP Display The displays or merchandising units used at the point of purchase.

Porosity The property of paper that governs the degree of permeability, I.e., the passage of a substance through it.

Post Cure The continuation of a polymerization (curing) process within a UV ink or coating, after exposure to UV radiation has been

terminated.

Pot Life The time period during which an adhesive or coating remains effective and workable.

PP Polypropylene.

Pre-Separated Art Artwork in which the basic layout, register marks and major color is prepared on illustration board and each additional color plate is drawn on a separate sheet or film overlay.

Press In-Line Press with the printing units in-line.

Press Proofs Printed sections of substrate material made on a press to allow for approval or final corrections before the production

printing run is made.

Color Label Press University "Glossary of Terms" Part Sixteen, Course One

Over the last few years I've blogged about the importance for dealers to diversify to other avenues of print. Especially if they want to stay in the "break and fix" model for servicing and selling devices that print. One of those opportunities is color label printing.

The list of the types of color labels is enormous. Bumper stickers, political stickers, custom groceries, branding, safety, food labels, CBD, beer & wine, cannabis, the list goes on and on. Post COVID19 recovery will require many companies to purchase, print labels and signs.

Post COVID19 will also see a drop in printed pages across the world, we have all learned to do more with less. That less means printers and copiers. What is your Post COVID19 recovery plan? Keep doing what you've always been doing or forge a new path where print still matters.

Label Press University

At the top of each blog you'll see ![]() . Clicking that link which is at the top of each blog will then bring you the collection of blogs for Color Label Press University. It's pretty neat, you'll see all of the blogs that we've posted for an easier read and simple way to toggle from blog to blog.

. Clicking that link which is at the top of each blog will then bring you the collection of blogs for Color Label Press University. It's pretty neat, you'll see all of the blogs that we've posted for an easier read and simple way to toggle from blog to blog.

Color Label Presses can be used as seeding devices in larger Print4Pay opportunities, or help that dealer or rep get a conversation going with an account where they have never had any traction with MFP's or IT services. In addition, the competition is ripe for takeover. Let us not forget about the GP!

The market for full color digital labels in huge and the potential to make some serious commissions is enormous. BTW, isn't that why we're in this crazy business?

Color Label Press University "Glossary for Pressure Sensitive Labels" Course One (Sponsored by Muratec a Konica Minolta Company)

Application of a clear film to a label stock for the purpose of protection or to enhance graphic quality, usually done in-line on the press.

Overlap In applying a label around a bottle or container, one end extends over the other and adheres to itself.

Overlay In artwork, a transparent film or tissue over copy on which color breaks, instructions or corrections are indicated. Also, transparent prints which, when combined or overlaid, form a composite picture.

Overrun Production manufactured in excess of the specified order quantity. (Industry standard +/-10%).

Oxidation The chemical reaction involving the process of combining with oxygen to form an oxide. The deterioration of an adhesive film due to atmospheric exposure. The breakdown of a hot melt adhesive due to prolonged heating and oxide formation.

Packaging A coordinated system for the preparation of goods for shipment, distribution and storage.

Padding Binding sheets of paper - blank, ruled, etc., together by applying flexible glue or adhesive to one edge of the stack.

Pass One trip for the material through a production piece of equipment. Certain constructions require additional passes to complete the production.

Pattern Coated Refers to the width and spacing arrangement of strips of adhesive laid down parallel to machine direction and across the

width of pressure sensitive label stock during its manufacture. Also refers to adhesive coating applied in a pattern which is not related to web direction.

Pattern Varnish Spot varnish applied to the printed surface in a desired pattern.

PCS Print Contrast Signal. A measurement of contract between the bars an dspaces of a symbol. A minimum PCS value is needed for a symbol to be scannable. PCS values can be calculated an displayed automatically on suitable instruments.

Pearlescent Pigments A class of pigments consisting of particles that are essentially transparent crystals of a high refractive index. The optical

effect is one of partial reflection from the two sides of each flake. When reflections from parallel plates reinforce each other, the result is a silvery luster. Effects possible range from brillant highlighting to moderate enhancement of the normal surface gloss.

Peel Adhesion Peel adhesion is the force required to remove a pressure sensitive label from a standard test panel at a specified angle and speed after the label has been applied to the test panel under specified conditions for a specific time period.

Peelback A method of separating a bond of two flexible materials or a flexible and a rigid material that have been bonded with an adhesive. The flexible material is pulled from the mating surface at a 90 or 180 degree angle to the plane in which it is adhered. The stress is concentrated only along the adhesive line of immediate separation.

Peeler Plate A sharp edged, flat piece of metal around which the backing or carrier material is threaded, the prime function being a

mechanical device which causes a pressure sensitive label to be dispensed from the backing material.

Penetration Change of appearance of the face material due to movement of one or more components from the adhesive or the labeled

surface. Bleed through, migration.

Perforated Refers to a series of small incisions made in laid-on labels and/or their release liner to facilitate tearing along a predetermined

line, or for fan folding.

Permanency A measure of an adhesive's ultimate holding power or bond strength. A permanent adhesive will develop a bond that makes label removal difficult or impossible without distorting the face stock.

Permanent Adhesive An adhesive characterized by having relatively high ultimate adhesion to a wide variety of surfaces.

Permeability The property of a material that allows or resists a substance to pass or flow through it; the rate of such passage.

Phosphorescent Face A face material coated with a phosphorescent ink, that emits light in a visible spectrum.

Photoinitiator In ultraviolet-curing systems, the chemical which, when expposed to UV light, breaks certain chemical bonds in the system

to start the chain reactions which cause polymer formation. This chemical is commonly referred to as a catalyst.

Photopolymer Plate material that is photosensitive and upon exposure, its compounds polymerize to form a tough, abrasion resistant surface which becomes the inking media.

Piecework Describes a payroll system generally used in production environments where employees are paid according to the actual

number of pieces produced in a given time period.

Piggyback Pressure sensitive constructions that have two release coated liners, two layers of adhesive and a face material which

allows a label to be applied, complete with backing, for future or further application.

Pigment Finely ground, solid particles used to give color or opacity to printing inks and coatings, and usually insoluble in such a

mixture.

Pin Feed See feed slots.

Pin Register The use of accurately positioned holes and special pins or pin bars on copy, film, plates and presses to insure proper register of color.

Pinch Roll See nip roll or pull roll.

Pinhole A very small hole which may permit the passage of light, moisture or electrical current.

Pinholing Refers to the failure of a printed ink to form a complete film. This condition will become visible by the appearance of small

holes in the solid print area.

Color Label Press University "Glossary of Terms" Part Fifteen, Course One

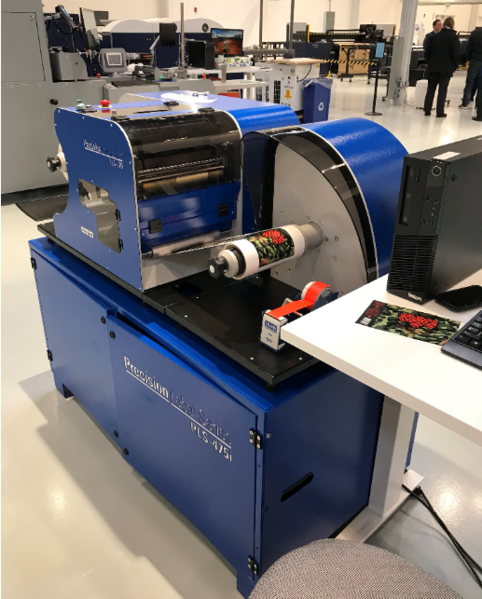

As I walked in the building the smell of fresh iron, virgin plastic and ozone told me I was in copier heaven! I told David Clearman (Director of Marketing and PLS Sales for Muratec Amercia) that the smell of copiers was in the air!

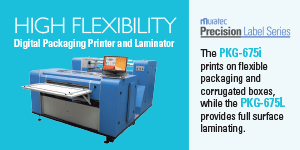

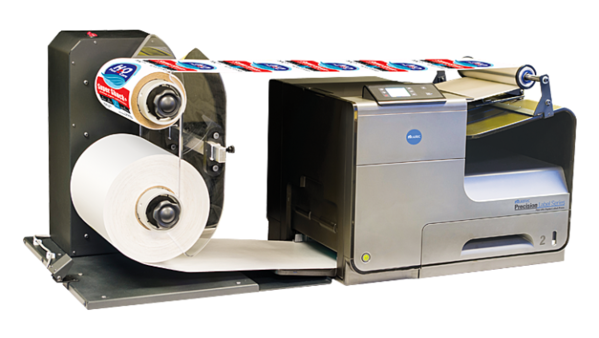

I was excited to take a tour of new KonicaMinolta CEC (Customer Engagement Center) in Ramsey, NJ and get personal with the PLS (Precision Label Series) PKG 675 and the awesome PLS 475i. The PGK 675 is designed for printing onto corrugated material and the PLS 475i is designed for printing full color labels. Both print devices the latest in memjet technology.

Nine percent growth for the label press devices and 22% growth for press packaging. Being such a hardware junkie this is music to my ears. Just a wonderful hour and I encourage all dealers to take a deep dive into this lucrative opportunity.

Yes there is a reduction of print happening in the office. But if I was a dealer principal in the business of putting ink or toner on paper don't I owe to myself to expand my services? The market is huge for digital label presses and digital packaging presses and there are more opportunities for net new clients than you can shake a stick at. Think about this the next time you make a purchase and take a look at all of the ink and toner!

Label Press University

At the top of each blog you'll see ![]() . Clicking that link which is at the top of each blog will then bring you the collection of blogs for Color Label Press University. It's pretty neat, you'll see all of the blogs that we've posted for an easier read and simple way to toggle from blog to blog.

. Clicking that link which is at the top of each blog will then bring you the collection of blogs for Color Label Press University. It's pretty neat, you'll see all of the blogs that we've posted for an easier read and simple way to toggle from blog to blog.

Color Label Presses can be used as seeding devices in larger Print4Pay opportunities, or help that dealer or rep get a conversation going with an account where they have never had any traction with MFP's or IT services. In addition, the competition is ripe for takeover. Let us not forget about the GP!

The market for full color digital labels in huge and the potential to make some serious commissions is enormous. BTW, isn't that why we're in this crazy business?

Color Label Press University "Glossary for Pressure Sensitive Labels" Course One (Sponsored by Muratec a Konica Minolta Company)

Non-Read Ink Any ink with a sufficiently high reflectance to prohibit detection by an optical scanner. Non-read inks are used as visual guides that do not interfere with data reading.

Non-Returnable Core Biodegradable. A disposable core composed structurally so as to make it suitable for one-time use.

Non-Volatile Refers to the portion of an adhesive, coating or sealer that does not evaporate or vaporize at relatively low temperatures.

Non-Woven Materials Usually refers to paper 'tissues' or synthetics like rayon.

Numeric A machine vocabulary that includes only numbers as contrasted to alphanumeric which includes both letters and numerals.

Nylon DuPont's trade name for a strong plastic film which has high oil and gas resistance; used a filament in strapping tapes, with high impact resistance.

Nyloprint BASF's trade name for photopolymer plate material.

OCR Optical Character Recognition. An information processing technology dealing with the conversion of imprinted or written data to another language and medium.

OCR-A An abbreviation commonly applied to the character set contained in ANSI Std. X3.17-1974.

OCR-B An abbreviation commonly applied to the character set contained in ANSI Std. X3.49-1975.

OD Outside diameter of a cylinder, roller or roll of labels.

OEM Original Equipment Manufacturer. One who produces a component or components used in the making of a finished assembled product.

Off-Cut That part of the trim width that is not utilized. Usually a narrow roll which is left over because the customer placed an order which does not utilize the full master roll width.

Off-Line Refers to devices that operate independently of a large central processing unit.

Offset A defect characterized by the partial transference of ink from a freshly printed surface to an adjacent surface, as that of another sheet, film or the backing paper in a roll. Also the accidental transfer of ink from the idler or other rolls in a press to the web.

Offset Paper A paper designed for use on presses with general characteristics to resist distortion from stretching or shrinking, freedom from fuzz and a smooth surface which will take ink evenly without 'set-off'.

Offset Powder A fine mist of powder sprayed between two sheets of stock during the press run to prevent the moist ink of one sheet from offsetting onto the back of the succeeding sheet. Also used as a slip additive to assist stacking.

Offset Printing A process of indirect printing in which an impression of type or a design on a plate is printed on a rubber blanketed cylinder from which it is impressed, I.e. offset upon the surface to be decorated.

Offsetting Describes the unwanted transfer of ink from one printed surface to another surface.

Olefins A group of unsaturated hydrocarbons of the general formula CnH2n, and named after the corresponding paraffins by the addition of 'ene' or 'ylene' to the stem.

Oleo Resins Semi-solid mixtures of the resin and essential oil of the plant from which they exude, and sometimes referred to as balsams.

Oleoresinous materials also consist of products of drying oils and natural or synthetic resins.

Oligomer A chemical compound whose molecules consist of a group linked monomers. This is a compound intermediate in size between the single monomer unit and the huge polymer molecule.

On-Line An operation in which peripheral devices are connected directly to the computer central processor.

One Component Adhesive A pressure sensitive adhesive in which all of the necessary properties are derived from a single uniquely designed synthetic

polymer.

Ooze Adhesive moving out of ends of rolls or stacks of sheets causing ends to feel sticky and possibly causing material to block. Adhesive cold flow.

Opacimeter The instrument with which the degree of opacity may be measured.

Opacity The measure of the amount of light that can pass through a material. The hiding property of an ink film; property of film allowing printed material to show through in varying degrees.

Opaque Ink An ink that is not transparent and reflects only its color regardless of what colors it overprints.

Opaqueness The degree of opacity.

Operating Range The sum of a scanner's optical throw and depth of field.

Operating Side That side of a label press on which the printing unit adjustments are located. Opposite of driving side or gear side.

OPP Oriented polypropylene.

Optical Relates to the utilization of light. Sometimes involves the use of light sensitive devices to acquire information.

Optical Character Reader An information processing device that accepts and processes machine or hand written characters.

Optical Throw The distance from the face of the code reader or scanner to the beginning of the depth of field.

Opticite Film Trademark of a label film supplied by Dow Chemical (polystyrene type).

Orange Peel Rough coating causing an 'orange peel' appearance. See mottle.

Orientation The alignment of the crystalline structure in polymeric materials so as to produce a highly uniform structure. Can be accomplished by cold drawing or stretching during fabrication. Also, the alignment of bars and spaces to the scanner.

Original The material that is required to be reproduced in the printing process. Usually a photograph, transparency, art, artist's

Color Label Press University "Glossary of Terms" Part Ten, Course One

In the past I've called my self a hunter of wide format devices. I'm know moving on to call myself a hunter for color labels, which will lead me to placing net new label presses.

Over the last month or so, I've noticed multiple rolls of color labels in Wawa's, Quick Chek (both of these are gas station/food markets here in New Jersey). In addition I also scoped multiple rolls of labels in McDonalds and Dunkin Doughnuts (or Dunkin as they have re-branded). See and ye shall find color labels everywhere!

Ink is all around us, while pages are reducing in the office, ink usage for branding is on fire. Next time you're at you're favorite gas convenience store, stop and take a look at the opportunities, you'll be floored!

Label Press University

At the top of each blog you'll see ![]() . Clicking that link which is at the top of each blog will then bring you the collection of blogs for Color Label Press University. It's pretty neat, you'll see all of the blogs that we've posted for an easier read and simple way to toggle from blog to blog.

. Clicking that link which is at the top of each blog will then bring you the collection of blogs for Color Label Press University. It's pretty neat, you'll see all of the blogs that we've posted for an easier read and simple way to toggle from blog to blog.

Color Label Presses can be used as seeding devices in larger Print4Pay opportunities, or help that dealer or rep get a conversation going with an account where they have never had any traction with MFP's or IT services. In addition, the competition is ripe for takeover. Let us not forget about the GP!

The market for full color digital labels in huge and the potential to make some serious commissions is enormous. BTW, isn't that why we're in this crazy business?

Color Label Press University "Glossary for Pressure Sensitive Labels" Course Six (Sponsored by Muratec a Konica Minolta Company)

Flock A commercial fuzz or lint consisting of fine strands or filaments from textile fibers, animal hair, synthetic resins, etc. It is applied to an adhesive coated surface to produce a decorative felt-like appearance.

Flood Coat The coating of an entire surface with an ink, adhesive, coating, etc.

Flow Out The capacity of an ink or adhesive to spread, filling in the hills and valleys on the surface of the printed or non-printed substrate.

Fluorescent Paper A paper that is coated with a fluorescent pigment which not only reflects a visible wave length, but is activated by most of

the remaining absorbed light to re-emit it as color of a longer wave length which results in reinforcement of the reflected color.

Fluorescent Pigments By absorbing unwanted wave lengths of light and converting them into light of desired wave lengths, tehse colors seem to

possess an actual glow of their own.

Fluorocarbon Films A film with very high and low temperature limits, excellent electrical characteristics, and a very slippery, non-sticking surface.

Flying Splice A splicing or joining of two webs accomplished while the web is in motion.

Foaming A property of a liquid related to a surface tension. Frothing.

Focal Distance Ultraviolet light energy, like visible light, can be collected and focused by an elliptical reflector. The focal distance is the distance from the lamp to the substrate, whereas the maximum energy is concentrated at that distance which gives the narrowest band of focused light.

Foil A very thin metal sheet that can be used as face stock material in label production.

Foil Paper Laminate A foil laminated to a sheet of paper used as a face stock. The foil is usually top coated to improve ink receptivity.

Font In composition, the complete assortment of type of one size and face.

Format The size, style, layout, margins, etc., of a label.

Fountain A pan or trough on a flexographic press which contains the ink and in which the fountain roller revolves.

Four-Color Process Printing with yellow, magenta and cyan color inks plus black, using screens to create all other colors.

Freezer Adhesives Adhesives that will function at temperatures below the freezing point. They are usually removable at room temperatures.

Fuse To join two surfaces by heating them to their melting or softening point.

Gapping Openings between layers within a roll of self wound laminating tape.

Gauge A unit of measure usually the thickness or diameter and generally express by a number.

Gauge Bands Areas where material or liner is thicker, forming a hard ridge as layer after layer builds up in the same spot.

Gear Chart A handy reference compilation of the various printing lengths, or repeats, obtainable within the different gearing systems.

Gear Marks A defect in flexographic printing. Usually appears as uniformly spaced, lateral variations in tone exactly corresponding to the

distance between gear teeth.

Gear Streaks In printing, parallel streaks appearing across the printed web at the same interval as the gear teeth on a cylinder. Same

gear marks.

Gel A state or condition in which an ink, varnish or coating has a jelly-like consistency.

Gelling The thickening of an ink or other liquid, which cannot be reversed by stirring.

Ghosting (New) Vary faint reproduction of printed design without actual ink transfer.

Ghosting (Old) Shadows or indistinct images appearing in solids or reveses typically caused by poor ink distribution and/or poor base ink

formulation.

Glassine A super calendered, smooth, dense, transparent or translucent paper manufactured primarily from chemical wood pulps which have been beaten to secure a high degree of hydration of the stock. Sometimes used as a backing paper.

Gloss Characteristic of the surface which causes it to reflect light at a given angle..

Grab Ability of an adhesive to quickly adhere to a surface with a minimum of pressure (usually touched to the surface with its own

weight). Also called instant adhesion or initial tack.

Grain In papermaking, the direction in which most fibers lie corresponding with the alignment of the fibers in the direction of the

paper travel through the paper machine.

Gram Unit of weight in the metric system; the weight of one cubic centimeter of water at standard conditions. 28.35 grams equal

one ounce.

Gravure Printing A printing process employing minute engraved wells. Generally, deeply etched wells carry more ink than a raised surface,

hence print darker values. Shallow wells print light values. A doctor blade wipes excess ink from the cylindrical printing surface. Rotogravure employs etched cylinders and web fed stock.

Guard Bars The bars which are at both ends and center of a UPC and EAN symbol. They provide reference points for scanning.

Guillotine An instrument for trimming sheets of paper (with a downward cutting action).

-=Good Selling=-

Color Label Press University "Glossary of Terms" Part Nine, Course One

Yes, Since Summer is winding down, I thought I'd get back in the groove with the glossary of terms for Color Label Presses.

It was a few months ago when I went cold calling in South Jersey. I was on the lookout for copiers but also wanted to keep my eyes open for companies that could benefit from a label press or a corrugated press. If you're not familiar with a corrugated press that device will allow a user print graphics for use on card board boxes.

I was able to find three companies that could be deemed as a suspects. Although not a suspect for me at this point in time.

The largest potential came from a franchise operation. One of the items I noticed was cardboard boxes that were covered with ink with the companies branding. Yes, it was time to ask some questions about those boxes. I found out that this particular location went through and average of 5 boxes per week. Next question was "how many locations are there?" I was floored with when I heard almost 1,500 locations. Taking the average of 5 boxes per week and then multiplying by the locations meant that they could be using 30,000 boxes a month. Annual would be around 360,000 boxes. That my friends is one hell of a suspect and a follow up is in order.

Ink is all around us, while pages are reducing in the office, ink usage for branding is on fire. Next time you're at you're favorite gas convenience store, stop and take a look at the opportunities, you'll be floored!

Label Press University

At the top of each blog you'll see ![]() . Clicking that link which is at the top of each blog will then bring you the collection of blogs for Color Label Press University. It's pretty neat, you'll see all of the blogs that we've posted for an easier read and simple way to toggle from blog to blog.

. Clicking that link which is at the top of each blog will then bring you the collection of blogs for Color Label Press University. It's pretty neat, you'll see all of the blogs that we've posted for an easier read and simple way to toggle from blog to blog.

Color Label Presses can be used as seeding devices in larger Print4Pay opportunities, or help that dealer or rep get a conversation going with an account where they have never had any traction with MFP's or IT services. In addition, the competition is ripe for takeover. Let us not forget about the GP!

The market for full color digital labels in huge and the potential to make some serious commissions is enormous. BTW, isn't that why we're in this crazy business?

Color Label Press University "Glossary for Pressure Sensitive Labels" Course Six (Sponsored by Muratec a Konica Minolta Company)

Face-Cut Label: Any pressure sensitive label where the face material is cut to the liner.

Face Material: Any paper, film, fabric, laminate or foil material suitable for converting into pressure sensitive label stock. In the finished

construction this web is bonded to the adhesive layer and becomes the functional part of the construction.

Face Slit: A slit in the face material of a pressure sensitive produce to facilitate removal from the backing.

Face Stock: See face material.

Fadeometer: Instrument used to measure the fade resistant properties of inks and other pigmented coatings.

Fading: A gradual decrease in brilliance of color. The term is often applied to the change in color produced by exposure to light.

Fan Fold: See continuous labels.

Fatigue: A condition of stress created by repeated flexing or impact force upon the adhesive-adhered interface.

Feathering: A defect which is characterized by ragged, coarse edges, or undersirable irregular edges around a print.

Feed Slots: Round or rectangular holes or slits put in pressure sensitive label stock to maintain the register of pressure sensitive labels

while they are being printed or imprinted.

Festoon: Material take-up system usually used with a butt splicer in order to continue feeding a press while the splice is being made

on stationary material.

Fill-In: Generally used to refer to the open portions of small type and half-tones filled by ink.

Filling-In: Refers to the filling-in of small reverse areas or copy of a printed design.

Film: A transparent material used for face stock for pressure sensitive labels. Often used in applications requiring maximum

durability.

Film Master: A photographic film representation of a specific symbol from which a printing plate is produced.

Film Positive: A positive contact print on a film base material.

Films: Face and liner material manufactured from synthetic high molecular weight polymers.

FINAT: European organization of label printers similar to TLMI.

Fineness of Grind: The degree of grinding or dispersion of a pigment in a printing ink or vehicle. Extent to which particle size has been reduced

to its ultimate by grinding technique.

Fineness of Grind Gauge: Instrument consisting of a flat block with two calibrated gradient slots from 0 to 0.001 inch on which ink is drawn down with a steel blade. Undispersed pigment or other particles in ink show streaks starting at their particle size.

Finish: The surface property of a material determined by its texture and gloss. Also an important physical property of paper. It describes surface contour and characteristics measurable by smoothness, gloss, absorbability and print quality. Finish of paper can be aesthetic or functional.

Finishing: Usually refers to the last thing done prior to shipping, I.e. rewinding, packing, etc.

Fish Eyes: Round or eye-shaped deformations in a coating (adhesive, release, protective, etc.); craters.

Flag: A marker, usually strips of colored paper or board, inserted in rolls of pressure sensitive materials and extending from an edge to designate a deviation from standard, such as a splice, defect or specification change. A warning to the operator handling the material during the next operation in the converting process, usually indicating an area that is to be inspected closely.

Flagging: Usually refer to the 'lifting' of a pressure sensitive label from the surface to which it has been applied. This condition most often occurs when the label has been applied around a curved surface.

Flame-Resistant Paper: A paper which has been treated with chemicals which enables it to resist flame. While not actually fireproof, it will not support combustion, will char but not carry a flame.

Flammable: Capable of being ignited.

Flash Point: The temperature at which a flammable liquid will flash when ignited by small flame passed over the surface.

Flat Pack: A continuous web folded at a cross perforation at regular intervals.

Flex: Another term for deflection of rolls or cylinders in press. Also, bending qualities or characteristics, of any material, including printing substrates.

Flexibility: A property of face materials, measured under specified conditions, that indicates how readily they will conform to curved surfaces.

Flexible Printed Circuit: A printed circuit or conductive pattern, on or between insulating layers, which remains flexible after processing.

Flexible Die: See magnetic die.

Flexing: Condition that can occur on a die when the die circumference is less than the width of the cross-blades. Causes the center of the cross-blades to fail to cut properly and consistently.

Flexlight: Union Carbide's trademark for photopolymer plate material.

Flexographic Printing: Formerly called aniline printing. A method of rotary printing that employs flexible, raised relief image plates and rapid-drying

inks.

Flexography: Relief printing process using a simple inking system and fluid inks.

-=Good Selling=-

Take Aways From MY Recent Trip to InfoFlex 2018

The next time I go to Indianapolis it's going to be by plane and not by car. It was a last minute decision on whether to make the trip or not. Thus when I looked at the flights and saw that the cost was almost a thousand bucks, I decided the make the drive. On the way out I did two six hour drives and stayed over night in western PA. But, the trip back I had to make in one day. It was fourteen hours from start to finished and I was mentally drained by the time I arrived home in Highlands.

Muratec America

A few weeks ago I was notified by my friends at Muratec America (Division of Konica Minolta) about the InfoFlex Event in Indianapolis. The InfoFlex event is for those businesses and professionals that use the process of flexography to print labels.

Here's the definition.

Flexography (often abbreviated to flexo) is a form of printing process which utilizes a flexible relief plate. It is essentially a modern version of letterpress which can be used for printing on almost any type of substrate, including plastic, metallic films, cellophane, and paper.

Flexography

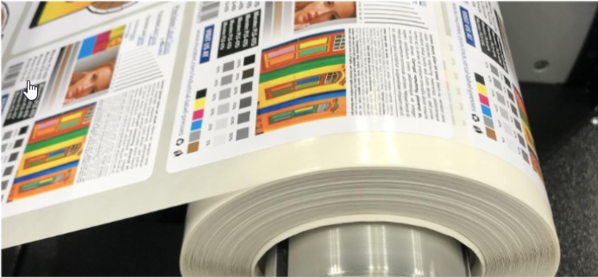

There's a few reason why I wanted to go. For starters a recent blog from GAP Intelligence stated that the digitization rate of four percent. That means that only 4% of the presses in use are digital. That market is ripe for the penetration of digital label presses. In addition, there are not many players offering digital label presses.

Secondly, I needed to learn more about Flexography and how those presses work. My last reason was to learn more about the label presses that are being offered by Muratec America. It's a different world from copiers, however it's a channel that is still thriving and when it comes down to it, it's all about putting ink or toner on substrates.

I walked the show floor twice before I gathered up the gumption (I had no clue as to what 90% of the vendors were selling) and thought of the questions that I wanted to ask. To everyone, I introduced my self as a beginner with Flexography. To my surprise everyone was willing to answer my questions and help me better understand flexography. Everyone that I spoke to was aware that digital presses (ink or laser) is the wave of the future.

Takeaways

1) My biggest take away is that Flexo presses are very similar to off-set presses. There are still plates, make readies (labels), waste, press cleaning, drum cleaning and set up times. Can take up to 25 minutes to

2) Flexo Presses can start at about $800K and go in to the millions of dollars!

3) Short run labels of 500-5,000 are frowned upon especially if they have a wide web flexo press.

4) Flexo Presses can create full color labels capable of cold foil, spot varnish and variable printing. Cost is measured in MSI (cost per one thousand square inches).

5) Flexo printing at least with some of the older devices still needs a craftsman to dial in the press and make it hum. Same as off-set.

6) There are no generic digital inks for Memjet or PageWide print heads. At least that's what I was told. I did have a conversation with a rep from TOYO inks and he stated that they do have a digital ink division (suggested that I speak to someone in their digital ink division), however they may have a relationship with HP.

Direct Correlation

For me the beginner, I see the direct correlation between off-set and Flexo for the placement of digital label presses. For those that want to get into this lucrative field we can take the same path that we used to replaced off-set presses many years ago. We're not go to be able to replace those Flexo presses at the start, however what we can offer is an alternative digital technology that can enhance a company that is using Flexo Presses. We need to address and attack the short run orders that that are turned away or are making a much smaller margin. Focusing on those short run orders to find placements for digital label presses.

Consumables & Maintenance

Ink, ink and more ink. Since there seems to be no generic inks available, selling label presses that uses the Memjet or PageWide print heads will make your dealership the "go to" source for the ink. If you're thinking about click charges there is none. Maintenance Agreements should be billed as "device billing", which means that the dealership can charge a month or annual cost with unlimited usage.

Comment

After a recent post on Linkedin about the event. Ray Stasieczko offered the comments below.

"Not without a solid business plan to understand the market potential and true cost to deliver. A dealer selling 5 or 10 won’t provide the ROI. These are no different than Production Print equipment too many chase revenue instead of profit".

I'm in agreement with the need for a solid business plan. But I'm not in agreement with the statement of a dealer selling 5-10 presses won't provide enough ROI. With an average selling cost of $45K per press, the sale of 10 presses will create almost a cool half a million of revenue. All of the ink consumables will be captured by the dealer, and depending on price a dealer may be able to capture much of the substrates that will be used.

Ray also stated that these label presses are no different that Product Print. I'm also in agreement with that. If your dealership is successful with selling Production Print, then the Label Presses should be a no brainer to move forward with. Think of it this way, if you can't get in the door with a Production Print, you may be able to create excitement and get in the door with Label Presses.

"Too many chase revenue instead of profit". I hear you Ray, but Label Presses allow you to chase revenue and extreme profit margins. The high GP's for Production Print has already past in most major markets. There's too much competition battling for the slice of the pie with cut sheet opportunities.

Opportunities for GP

If the opportunities to make GP continue to dwindle with MFP's, then how the heck are dealerships going to keep their best sales people. Let's not think about the old dogs like me, but those youngsters that are really good and you can't keep them because another industry offered them better opportunities to make bundles of cash. Do we really want a continuous revolving door with sales people? I don't think so. Wouldn't we want to them to make bundles of cash with us? Sales reps that make bundles of cash is also making piles of profit for the dealer.

Change is Good

There are many discussions in our industry about the need to change, and not be complacent. Yes, you can squeeze more profit from existing MFP accounts, and you can grow your business from acquiring other dealerships. But how long can that business model last with declining pages and everyone stealing each others accounts with net new pricing?

END

Will digital take over Flexo anytime soon? No, I don't thing so. Is there a market for digital ink or laser label presses? Absolutely there is. It's all about becoming a fan of the channel, and doing your homework (just like copiers).

Boy does this bring back memories from my duplicator days!

-=Good Selling=-

Color Label Press University "Where to Find Color Labels" Part One, Course Two

This blog will be an additional addition to our Label Press University. We're going to go in alphabetical order to educate everyone on products & industries that use labels.

About two months ago I counted all of the labels that were plastered on a Ricoh W3601 wide format MFP. I believe the total ended up at 36 or so. Labels are everywhere and the opportunities to place label presses are everywhere.

Appliances, Apparel, Automotive products, Agricultural products, Aerospace industry, Advertising agencies, Asset tags

Appliances, Apparel, Automotive products, Agricultural products, Aerospace industry, Advertising agencies, Asset tags

Beverages, Bottles, Boxes, Bumper stickers, Business cards, Bookplates, Beauty products, BBQ Sauce, Bakeries, Building materials

Beverages, Bottles, Boxes, Bumper stickers, Business cards, Bookplates, Beauty products, BBQ Sauce, Bakeries, Building materials

Candy, Cars, Coffee, Candles, Copiers, Corporate branding, Copackers, Cosmetics, Commercial printers, Cartons, Cannabis, Chemicals

Candy, Cars, Coffee, Candles, Copiers, Corporate branding, Copackers, Cosmetics, Commercial printers, Cartons, Cannabis, Chemicals

Dairy products, Discount pricing, Dog & other pet products, Day of the week labels, Distilleries

Dairy products, Discount pricing, Dog & other pet products, Day of the week labels, Distilleries

![]() Educational products, Electronic equipment and supplies, Essential oil products, Environmental notices, Emergency warnings

Educational products, Electronic equipment and supplies, Essential oil products, Environmental notices, Emergency warnings

![]() Food packaging, Folders, Fitness equipment, Fragile packaging, Floral products, Fundraising giveaways, Furniture products, Farming products

Food packaging, Folders, Fitness equipment, Fragile packaging, Floral products, Fundraising giveaways, Furniture products, Farming products

Glassware, Gifts, Games, Giveaways, GHS safety information, Grocery products, Gun labels, Gambling equipment

Glassware, Gifts, Games, Giveaways, GHS safety information, Grocery products, Gun labels, Gambling equipment

Healthcare products, Household chemicals, Hazard warnings Handle with care, Hot Sauce, HVAC repair labels, Honey, Hardware products

Healthcare products, Household chemicals, Hazard warnings Handle with care, Hot Sauce, HVAC repair labels, Honey, Hardware products

![]() Industrial chemicals, Industrial equipment, Inspection compliance, Instruction information, Inspirational messages

Industrial chemicals, Industrial equipment, Inspection compliance, Instruction information, Inspirational messages

![]() Jewelry, Jars, Juice bottles, Jeans and other clothing Journals, Janitorial products, Jellies and jams

Jewelry, Jars, Juice bottles, Jeans and other clothing Journals, Janitorial products, Jellies and jams

Kids' toys and products, Kitchen products, Ketchup bottles

Kids' toys and products, Kitchen products, Ketchup bottles

![]() Laboratory identification, Logo labels, Lotions, Laundry products Library books, Luggage, Lawn care products, Lighting equipment, Lumber products

Laboratory identification, Logo labels, Lotions, Laundry products Library books, Luggage, Lawn care products, Lighting equipment, Lumber products

Menus, Mailers, Maintenance reminders, Makeup, Medications, Medical supplies, Meat products, Machinery, Motorcycles and accessories

Menus, Mailers, Maintenance reminders, Makeup, Medications, Medical supplies, Meat products, Machinery, Motorcycles and accessories

![]() Nutritional products, Nutraceuticals, Newspaper advertisements, Name tags, Nail polish, Natural gas products, Nursery/gardening products

Nutritional products, Nutraceuticals, Newspaper advertisements, Name tags, Nail polish, Natural gas products, Nursery/gardening products

Office equipment and supplies, Oil and gas products, Organizational products, Olive Oil, Ophthalmic equipment

Office equipment and supplies, Oil and gas products, Organizational products, Olive Oil, Ophthalmic equipment

![]() Parking permits, Promotional products, Point-of-purchase signage, Pharmaceuticals, Petroleum products, Private label products, Produce

Parking permits, Promotional products, Point-of-purchase signage, Pharmaceuticals, Petroleum products, Private label products, Produce

QR codes, Quantity indicators, Quality control, Quilting products Quarantine labels

QR codes, Quantity indicators, Quality control, Quilting products Quarantine labels

![]() Retail Packaging, Railroad equipment, Recycling, Reorder notices, Repair labels, Restaurant supplies, Real estate promotions

Retail Packaging, Railroad equipment, Recycling, Reorder notices, Repair labels, Restaurant supplies, Real estate promotions

Specialty promotions, Safety, Security, School spirit, Shopping bags, Sporting goods, Static clings, Soda bottles, Sauces and spices, Soaps

Specialty promotions, Safety, Security, School spirit, Shopping bags, Sporting goods, Static clings, Soda bottles, Sauces and spices, Soaps

![]() Tracking information Tradeshow giveaways, Toys, Trophies, Tamper-evident notices, Telecommunication notices, Tobacco products

Tracking information Tradeshow giveaways, Toys, Trophies, Tamper-evident notices, Telecommunication notices, Tobacco products

![]() Updates on sales literature, UPC codes, USB flash drives, Uniforms, Utility notices, University-related products or services

Updates on sales literature, UPC codes, USB flash drives, Uniforms, Utility notices, University-related products or services

![]() Vending machines, Varsity promotions, Visitor labels, Veterinary products, Vaping products, Vitamins

Vending machines, Varsity promotions, Visitor labels, Veterinary products, Vaping products, Vitamins

Water Bottles, Warnings, Wine bottles, Wearables, Weight labels, Website promotions, Wedding favors or specialty items, Wholesale products

Water Bottles, Warnings, Wine bottles, Wearables, Weight labels, Website promotions, Wedding favors or specialty items, Wholesale products

X-ray machines and supplies, XL size labels, X-mas products

X-ray machines and supplies, XL size labels, X-mas products

![]() Youth organization activities, Yarn craft products, Yard care products, Yachts and yachting accessories

Youth organization activities, Yarn craft products, Yard care products, Yachts and yachting accessories

Zip code change notices, Zoo promotions, Zip tie labels, Zone labels

Zip code change notices, Zoo promotions, Zip tie labels, Zone labels

I'm sure there's some that we missed, please feel free to add in the comments section.

Still not sold on label presses? If you get a chance pay a visit to a Dunkin Doughnuts franchise. While you're waiting in line for you coffee, take a look at the entire store for labels. Take a look at the machines, the counter, windows, doors, walls. The amount of labels is incredible.

Special thanx to Muratec America a division of Konica Minolta for helping me with this blog. Interesting getting into the label press business? Call or email Muratec America and tell em the Print4Pay Hotel sent you.

-=Good Selling=-

Color Label Press University "Glossary of Terms" Part Seven, Course One

If you're a follower of this site, then you know that I'm a huge fan of Label Presses. They have sizzle, they have great margins and it's a great ROI sell to companies that are currently out-sourcing their labels.

About six months ago I took the time to draw up a business plan to set up a Label Press division in the dealership that I work for. Dedicated reps just focused on that one product means that you could have a team ramped up in just 90 days. Think back to when a copier dealership only have four models of copiers, the time that it took to get reps producing was usually 90 days or so. I never did deliver that business plan to the dealer principal, there was too much other stuff going on with acquisitions.

Kinda wish I did have a bankroll of $250K, because I know I could make it work. My goal with this blog series is to keep label presses in front of everyone. In addition if your margins are getting squeezed for copiers, maybe it's time to learn more about a market that has a low digitization rate of 6%.

At the top of each blog you'll see ![]() . Clicking that link which is at the top of each blog will then bring you the collection of blogs for Color Label Press University. It's pretty neat, you'll see all of the blogs that we've posted for an easier read and simple way to toggle from blog to blog.

. Clicking that link which is at the top of each blog will then bring you the collection of blogs for Color Label Press University. It's pretty neat, you'll see all of the blogs that we've posted for an easier read and simple way to toggle from blog to blog.

Color Label Presses can be used as seeding devices in larger Print4Pay opportunities, or help that dealer or rep get a conversation going with an account where they have never had any traction with MFP's or IT services. In addition, the competition is ripe for takeover. Let us not forget about the GP!

The market for full color digital labels in huge and the potential to make some serious commissions is enormous. BTW, isn't that why we're in this crazy business?

Color Label Press University "Glossary for Pressure Sensitive Labels" Course Six (Sponsored by Muratec a Konica Minolta Company)

Densitometer

Instrument that measures reflected or transmitted light. A reflection densitometer is used as a control instrument to check the uniformity and consistency of print color.

Depth of Field The range between the maximum and minimum distance from which a symbol can be read.

Destaticization Treating plastic materials to minimize their accumulation of static electricity.

Destructible Label See tamperproof label.

Detackification The destroying of the tack or stickiness of a pressure sensitive adhesive.

Die

Any of various tools or devices used for imparting or cutting a desired shape, form or finish to or from a material. A device in converting machinery used for cutting only the face material of a pressure sensitive laminate or for punching out shapes from the entire laminate or any other material.

Die Adapter

A device used to modify a die station of one type of press so that it will accommodate dies originally designed to be used on different presses.

Die Blades

Sharpened, thin steel blades used in flat or rotary dies. Also refers to blades on machine engraved or EDM manufactured rotary dies.

Die Cut To cut labels with a die. A term used to describe a label formed by die-cutting.

Die Cut Label Pressure sensitive labels mounted on a release liner from which the matrix has been die cut and usually removed.

Die-Cutting The process of using dies or sharp steel rules to cut any shape for labels.

Die Hold-Down Assembly

A steel block incorporating bearings which apply pressure to the bearer surface of a rotary die cutter through pressure screws.

Die Life Mileage expected from a new die and that expected following a re-sharpening of a die.

Die Lines A hand drawn or computer generated layout of the die cut shape or shapes on a clear or matte finish acetate or mylar.

Die Stain

Used to check die cutting accuracy. Usually done with diluted ink applied to the die cut surface of the backing or liner material. The ink wicks into any fractures of the silicone coated surface thereby exhibiting the problem areas.

Dielectric Dielectric values refer specifically to the insulating value of a material; a nonconductor of electric current.

Dielectric Paper

A dense, well formed, chemically pure papre used as an insulting material in electrical equipment to prevent the flow of electrical charges.

Dielectric Strength The voltage which a material will withstand without allow passage of the current through it.

Differential Release

A release liner with release coatings on both sides. One side has easy release while the opposite side is tighter such that the adhesive stays with the tighter side during winding and other subsequent converting.

Diluent A liquid used to thin ink.

Dimensional Stability

That property of a material which enables it to resist length, width, or thickness changes under varying conditions of heat, cold, moisture and other influences; ability to hold size, consistency of dimensions.

Direct Thermal Printing method utilizing heat impinged upon a specially coated substrate so that the heat turns the surface black.

Discoloration Any change from the original color, or an unintended inconsistency of color.

Discrete Code A bar code or symbol where the spaces between characters (intercharacter gap) are not part of the code.

Dispenser

A device that feeds pressure sensitive labels, either manually or automatically, making them ready for application. It can serve as a package for the labels as well (dispenser boxes).

Dispensing Edge

A relatively sharp edge around which a backing material is pulled in order to dispense a pressure sensitive label from the backing.

Dispersion A uniform distribution of solid particles in a vehicle.

Distorted Intentionally compensating for shrinkage, stretch, etc. of the flexographic printing plates.

Distortion Copy

Copy which is intentionally distorted in preparation, in order to compensate for the effects of dimensional changes due to subsequent processing. Flexographic rubber printing plates require such allowances to compensate for shrinkage, etc.

Doctor Blade

A thin flexible blade mounted parallel to and adjustable against the surface an engraved anilox roll for the purpose of scraping off excess ink or coatings.

Doctor Roll The fountain or metering roll in a flexographic press which doctors off excess ink from the engraved anilox roll.

Dot The individual element of halftones. All the dots in a halftone have equal density and spacing and vary in area.

Dot Etching Chemically reducing halftone dots to control the amount of color to be printed. Dot etching negatives increases color; dot etching positives reduces color.

Dot Gain or Spread

A printing characteristic in which dots print larger on the paper than they are on the films, causing darker tones or colors.

Dot Growth

The increase in size of a dot from the film to the printed sheet. Dot gain consists of two parts, physical dot gain and optical dot gain due to the physics of light absorption and reflection.

Dot Matrix Produces its printed image by firing pins or hammers against a ribbon and then onto paper.

Double Coated

A pressure sensitive product consisting of a carrier material with similar or dissimilar adhesives applied to the two surfaces and wound with a silicone release paper.

Downtime Nonproductive time caused by equipment malfunction, roll changes, plate or die problems, etc.

Draw-Down A method of roughly determining color shade by drawing down a small amount of ink with a meyer rod.

-=Good Selling=-

Would You Be Interested in Making a $90K Commission for Selling One Imaging Device?

I'm raising my hand, can you see it! I'm interested!

One of the main reasons that I'm still in sales is that I still have the desire to write my own pay check. Unexpected expense, no problem, just grind the gears a little harder and a little longer and you can make the cash that you need. I'm sure that's the same for many of my peers that are in the copier business.

Twenty or so years ago, I had visions of grandeur that maybe just maybe one day I might be selling a really high end product (jets, yachts) and make some serious cash. But, those weeks fell into months, then years and twenty years later I'm still in the same industry (that's not a bad thing). My chance never came or maybe it did come and I didn't see it.

About five or so years ago, I thought that Production Print devices would pan out to be a source of larger commissions. However, the manufacturers direct operations put the kibosh on that idea years ago when most decided that they'll drop their drawers on price just to get the box moved.

$90K Commission Check

Can you imagine getting a $90K commission check for selling one imaging device? That would be awesome! I also understand that in order to make the full $90K, a lot of things would have to go right, along with being in the right place at the right time.

Ok, right time, right place, everything to fall just right so that we could secure the order. Seems to me, that's something that we (salespeople) are experiencing every day of the week. When was the last time you had an opportunity to bring home a $90K commission check? I think about the margins that I have to work with. In order to make $90K on one device for one sale I'd have to have $300K of GP built it. Ah, that's not going to happen with selling just one copier or even a few production systems.

But, what I can tell you is that YOU can have these types of 90K commission opportunities. Dang, I can have these types of 90K commission opportunities.

Times are changing, hardware is changing and I'm all for it. Recently I was able to secure a copy of the pricing and commission structure for Muratec America a Konica Minolta Company complete line of Color Label & Packaging devices. I was blown away with the commission structure that is being offered for sales agents!

Did I mention the sales agent part?

Muratec is looking for sales agents in specific markets to sell their entire line of Color Label Press Series.

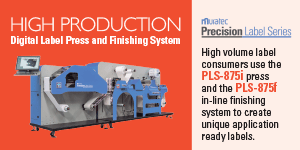

Let me get back to the opportunity to make that $90K commission check. Earning that $90K would mean that you would have sold their high end PKG-675i PKG & PKG-675L system. Now, I understand that opportunities like this are not an every day occurrence, however I also understand that every day beings a new opportunity. Sooner or later you will run into one of these opportunities and wouldn't it be grand that you're at least in the running to garner and order like this?

Let me get back to the opportunity to make that $90K commission check. Earning that $90K would mean that you would have sold their high end PKG-675i PKG & PKG-675L system. Now, I understand that opportunities like this are not an every day occurrence, however I also understand that every day beings a new opportunity. Sooner or later you will run into one of these opportunities and wouldn't it be grand that you're at least in the running to garner and order like this?

There are also five other models of Color Label Presses that Sales Agents can sell. Those commissions start at $7,000 and runs up to $82,000, depending on what model you sold. In addition one of the best points of the program is that Sales Agents only sell. All of the supplies, support, setup and training is handled by Muratec America.

I'm not writing this because Muratec America

I'm not writing this because Muratec America asked me to, nor am I getting paid to write this blog. I'm writing this because I'm exciting that finally I could have the opportunity to make some serious commissions. I can finally have leave that dream of having the opportunity to sell some big ticket items that are in my wheelhouse of knowledge. Imaging is imaging, we're just using a different process to the image on the substrate.

The other reason for writing this is because I believe there are many of us that are not happy with what has happened to the copier business in the last seven years. Margins shrinking, longer sales cycles, tons of competition, and let's face it all of our devices from all manufacturers perform well and are almost identical in what they do.

Am I stepping out on this new adventure?

I'd like to, but there are many things I need to address on a personal, financial and business level before I make the jump. I may never make that jump, but I believe that there may be others who are reading this blog that may be ready for something new, something different, something exciting and something that can pay some big bucks.

What I can tell you is that I want to have opportunities like these.

-=Good Selling=-

Five Reasons Why Every Manufacturer Needs A Color Label Print Device

Color labels....., now you seem and now you don't. Over the years I'll admit that I never paid much attention to color labels, yet they are everywhere you look.

Color labels....., now you seem and now you don't. Over the years I'll admit that I never paid much attention to color labels, yet they are everywhere you look.

Regulations and safety compliance in the work place has helped the color label market to explode in recent years.

Most small to mid size manufacturing companies are outsourcing their color labels, which means a very long wait time when placing orders and most are ordering way more than they need to bring the cost per label price down.

Kind reminds me of the early days of color copiers and printers. Most companies outsourced all of their color documents from flyers, forms, drop offs, hand outs and brochures. Once they did the math, most companies agreed that they should have color device on hand and move to print as needed aka print on demand.

The same is now true with the color label industry for those small to mid-size businesses or even larger work groups.

1. Does your company buy more than five hundred color labels per month? If so, you may want to re-think that outsourcing and have a device that can color print labels on demand.

2. Wasted labels can be a huge pain in the butt, especially when there is a regulation of compliance change. Those five thousand "Right-to-Know" labels that you just purchased are now obsolete when there is a change with a regulation or compliance change. How much did they cost?

3. Misplaced label orders or delayed label orders can bring the manufacturing process to a dead stop. Orders are then backed up and clients are thinking twice about ordering products from your company. It's an avoidable scenario.

4. You've waited three weeks for your new 5,000 custom color labels. Upon opening the box, you find there is a misprint/typo with those labels. Can you afford to wait another three weeks for a replacement order?

5. Inventory of pre-printed color labels requires additional floor space along with a higher financial burden carrying for that inventory.

Companies are realizing that having a centralized, on-demand color labeling device is the right device choice for companies to respond quickly to client changes/needs and compliance/regulatory issues.

-=Good Selling=-