It was about two weeks prior to Christmas that I visited Peddler's Village in Lahaska, PA. Peddler's Village offers many shops in colonial style buildings along with dining and lodging. Our mission was to shop for some Christmas gifts and we planned for a day of cold rain and raw conditions.

As I was forced to go in out of almost every shop on the campus I noticed that almost all of the shops had custom color branding labels for most of their food products. Below is a picture I took from the jerky shop.

Each package has a custom color label. Thus I did some investigative work to see if this shop produces the labels. I found some partially opened boxes of the the jerky and determined that these labels were produced at the time of packaging. In addition the company that supplied the jerky is located in PA.

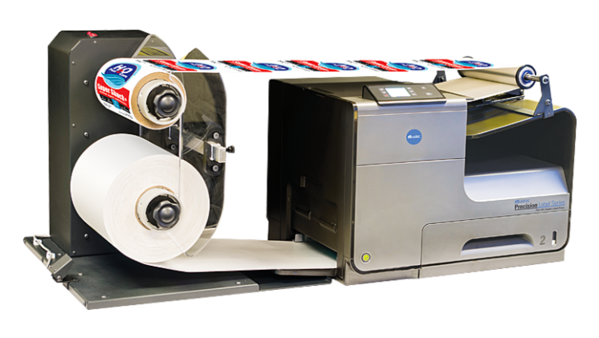

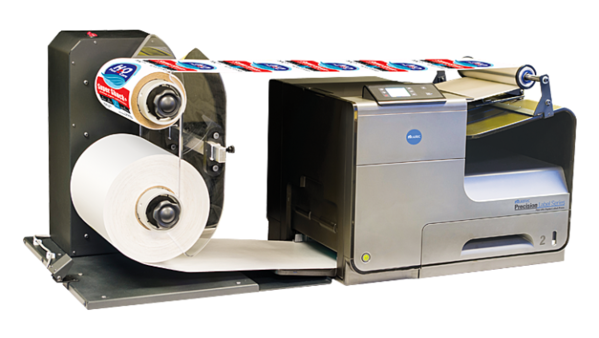

I knew then that this company could be a great suspect for a color label press. With the recent demise of clicks the addition of adding color label presses can make a difference to a dealers bottom line. It can also offer up additional opportunities for a great consumable revenue stream.

Label Press University

At the top of each blog you'll see ![]() . Clicking that link which is at the top of each blog will then bring you the collection of blogs for Color Label Press University. It's pretty neat, you'll see all of the blogs that we've posted for an easier read and simple way to toggle from blog to blog.

. Clicking that link which is at the top of each blog will then bring you the collection of blogs for Color Label Press University. It's pretty neat, you'll see all of the blogs that we've posted for an easier read and simple way to toggle from blog to blog.

Color Label Presses can be used as seeding devices in larger Print4Pay opportunities, or help that dealer or rep get a conversation going with an account where they have never had any traction with MFP's or IT services. In addition, the competition is ripe for takeover. Let us not forget about the GP!

The market for full color digital labels in huge and the potential to make some serious commissions is enormous. BTW, isn't that why we're in this crazy business?

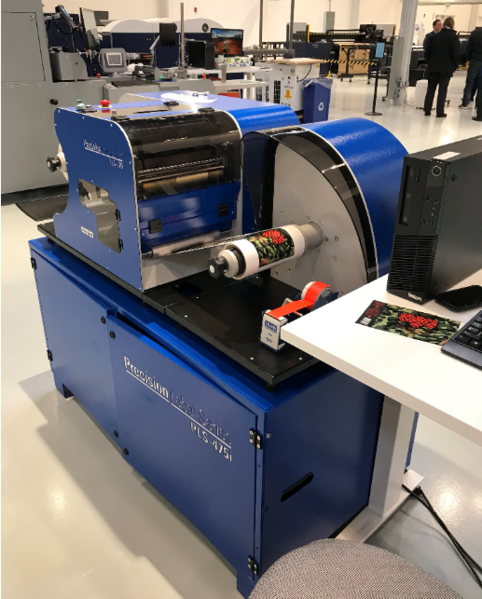

Color Label Press University "Glossary for Pressure Sensitive Labels" Course Nineteen (Sponsored by Muratec a Konica Minolta Company)

Register The corresponding placement of one color to the next, etc., as well as the printing placement as it relates to die-cutting, scoring, perfing, etc.

Register Marks Symbols attached to original copy prior to photography, used for positioning films in register, or registering two or more colors when printing.

Relative Humidity The amount of water vapor present in the atmosphere, expressed as a percent of maximum that could be present at the same room temperature.

Release The force required to free or separate a pressure sensitive label from its release liner, using a specific measuring device.

Release Agent Materials used to facilitate the removal of molded items from their molds. These agents can cause serious problems in adhesion when applying labels to the molded products.

Release Coat The release liner treatment material that allows pressure sensitive labels to release from the release liner. Usually made

from silicone.

Release Coat Transfer The transfer of release coat from the release liner to the pressure sensitive adhesive during release.

Release Liner The component of th epressure sensitive label stock which functions as a carrier for the pressure sensitive label. Prior to application, it protects the adhesive, and readily separates from the label immediately before the label is applied to product.

Relief Angle The angle of the raised portion of a printing plate.

Removability A relative term applied to pressure sensitive labels to describe the force or condition under which they can be removed from

a substrate. A removable label would be one in which no damage or staining occurs to the substrate or the face material on removal.

Removable Adhesive A pressure sensitive adhesive characterized by low ultimate adhesion and clean removability from a wide variety of surfaces.

Rendering The finished production of a design, drawing, painting, etc. by hand using any of various artist tools, I.e. pencils, pens, knives, brushes, air brushes.

Repeat The printing length of a plate cylinder, determined by one revolution of the place cylinder gear.

Repositionable The ability of a pressure sensitive label to be bonded to a surface, removed and repositioned. This can only be done for a

limited period of time (20 minutes). Beyond that time, the bond may begin to become permanent, except in cases where a removable adhesive is used.

Repositionable Adhesive A permanent adhesive that can be removed and re positioned for a short, finite time after application.

Repositioning The re-lamination of labels to a different location on the backing sheet following die-cutting.

Residue Something that remains after a part is removed, such as removing a label and leaving adhesive on the surface.

Restivity The ability of a material to resist passage of electrical current either through its bulk or on a surface. The resistivity unit of volume is the ohm-cm.

Retarders Combinations of liquids, solvents and extenders that are added to an adhesive, coating or ink to slow down the drying rate of

the material.

Reverse Printing Printing on the underside of a transparent film. Also, a design in which the copy is 'dropped-out' and the background is

printed making the copy appear in the color of the background.

Reverse Roller Coating The coating is pre-metered between two rolls, then wiped off onto the web, which is driven by a third backup roll. The

amount of coating is controlled by the gap between the metering and applicator rolls and also by relative speed or rotation between the same two rolls.

Rewind The take-up spindle or mandrel on a press. Also, the act of winding a roll of material through a machine to effect the opposite unwind.

Rewinding & Inspection The operation of winding the material from the press roll onto a core (or coreless) to produce rolls of the desired width,

diameter and tension. Out-of-spec labels can be removed during this operation.

Right Reading An image whose parts are spatially oriented to each other as they are on the original or as they are to be printed, in contrast

to the way they would appear reflected in a mirror.

Rockwell Hardness A method of determining the surface hardness of a substance. Degree of hardness.

Roll Coater A machine utilizing rolls to mechanically apply an adhesive or coating to flexible substrates.

Roll Label Pressure sensitive labels that are produced in a continuous roll form.

Roll-To-Roll A method of running materials through a printing machine. A roll of material is fed into a printing unit, is printed, then is rewound into a roll as it exits the machine.

Roll-To-Sheet A method of running material through a printing machine. A roll of material is fed into a printing unit, is printed, then is sheeted as it exits the printing machine.

Rotary Press A press that in normal use featutrees a roll-to-roll operation.

Rotary Printing Accomplished by means of a cylindrical impression cylinder and a cylindrical printing plate.

Rotogravure Printing Printing process that utilizes cylinders that have the design etched into the metal surface. The material to be printed comes in contact with the etched cylinder (which is carrying the ink) and the ink is transferred. A rubber pressure roll facilitates this transfer. Also known as gravure printing.

Rough Sketch An impromptu drawing of a picture or design, often in color. Often developed into comprehensive artwork.

Rub Test Test performed to determine the durability and abrasion resistance of the printed surface of a label